A guide to choosing the right material for plastic injection molding

Plastic injection molding is rapidly replacing traditional manufacturing methods as the preferred production method for B2B and original equipment manufacturers. At SZOMK, we know that choosing the right resin for injection molding is very important. This is why we work closely with each customer to ensure that our design and engineering teams understand the unique needs of each customer we work with.

Below you can find a brief overview of the materials we use in injection molds. If you are still confused about these materials, please feel free to contact us at +86 075583222882 or info@szmolding.com. We are happy to answer any questions you have and discuss the correct resin for injection molding products.

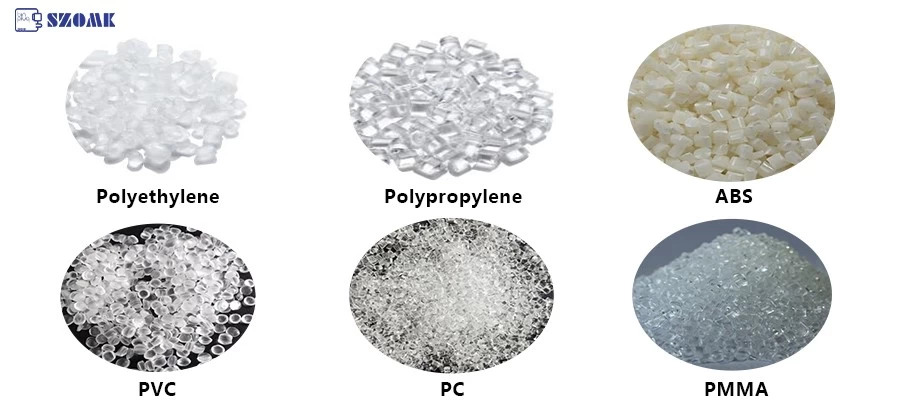

Polyethylene

To date, the most common plastic polyethylene accounts for approximately 34% of the entire plastics market. Polyethylene comes in many different forms, which makes it very useful in prototyping. Due to its high chemical resistance, it is also very suitable for packaging applications, especially when food is involved. Therefore, it is widely used to make plastic bottles, bags, trays, and containers.

Polypropylene

Similar to polyethylene, polypropylene is a heat-resistant polymer with high chemical resistance. The advantage of polypropylene is that it is tough, but not hard, which makes it able to withstand repeated use. It also has a strong ability to absorb moisture. Therefore, it is widely used to make living hinges, pipes and fluid applications, food containers, tableware, cups.

Acrylonitrile Butadiene Styrene (ABS)

ABS resin is a copolymer of styrene (SM), acrylonitrile (AN) and butadiene (BD) as the main raw materials. ABS has extremely excellent mechanical properties, dimensional stability, processability, chemical resistance and first-class appearance. These advantages make ABS resin an excellent engineering plastic. It has been widely used to manufacture machinery, electronic parts, electrical and household appliances, auto parts, medical products, food and drinking water containers, construction materials, toys and sports goods, and cosmetic containers.

Polyvinyl Chloride (PVC)

PVC is one of the most common thermoplastics. It has extremely high rigidity and has properties similar to acrylonitrile butadiene styrene (ABS). PVC has a natural white color and has a higher density than other plastics. Although PVC is rigid, it can be softened and used in combination with other plasticizers to make it more flexible. PVC is also flame retardant. Therefore, it is often used in the production of pipes, buildings, floors, and cable insulation.

Polycarbonate resin (PC)

It is a polycarbonate (PC) resin polymerized using the double hydroxy compounds of bisphenol-A (BPA) and the carbonate compounds of diphenyl carbonate (DPC). This resin provides glass-like transparency, high heat resistance, ultra-high impact resistance and dimensional stability. Suitable for various applications. It is also compatible with other materials such as ABS and PET, creating diverse alloy products. It contains no chlorine, so it is not corrosive. In addition, it is also suitable for disinfection with ethylene oxide and gamma rays, so it can be used in medical equipment. So this material is suitable for all 3C products, precision machinery, instrument products, auto parts, sports goods, sanitary products, and food and water contact materials.

Acrylic (PMMA)

Polymethyl methacrylate, usually referred to as acrylic PMMA, is a relatively cheap material, with good weather resistance and heat resistance, and extremely high transparency and gloss, while having stable physical, chemical, optical and Electricity and other characteristics. The transparency advantage of acrylic PMMA makes it ideal for applications requiring high visibility. It is easy to shape and can be cut into various forms without sacrificing its resistance to ultraviolet rays and scratch resistance. It can be widely used in electronic panels, mechanical parts, clock face shells, automobile and motorcycle indicator lights, telecommunications equipment, insulating parts, and sunglasses.

SZOMK injection molding service

In providing design advice, engineering assistance and helping to meet industry regulations, we are honored to have a team of experts who will be happy to guide you through the entire manufacturing process from initial consultation to product distribution and transportation.

Interested in discussing with someone on our team which material is best for your product? Contact us today! A member of our team will contact you within 8 hours to discuss your project in more detail.